A Detailed Mathematical Analysis of Chicken Grain Cost

/Elizabeth Rennert - rgf Staff

For a while, Red Gate Farm has mixed our own chicken grain, after purchasing each of the components (corn, soy, barley, etc.) separately. Recently, however, we’ve switched our chickens over to premade Poulin Grain layer pellets.

My goal is to figure out which is more cost-effective, mixing our own grain or buying premade pellets. Since I already have the price per 50 pound bag of the layer pellets, I want to calculate the cost of 50 pounds of our mixed chicken grain.

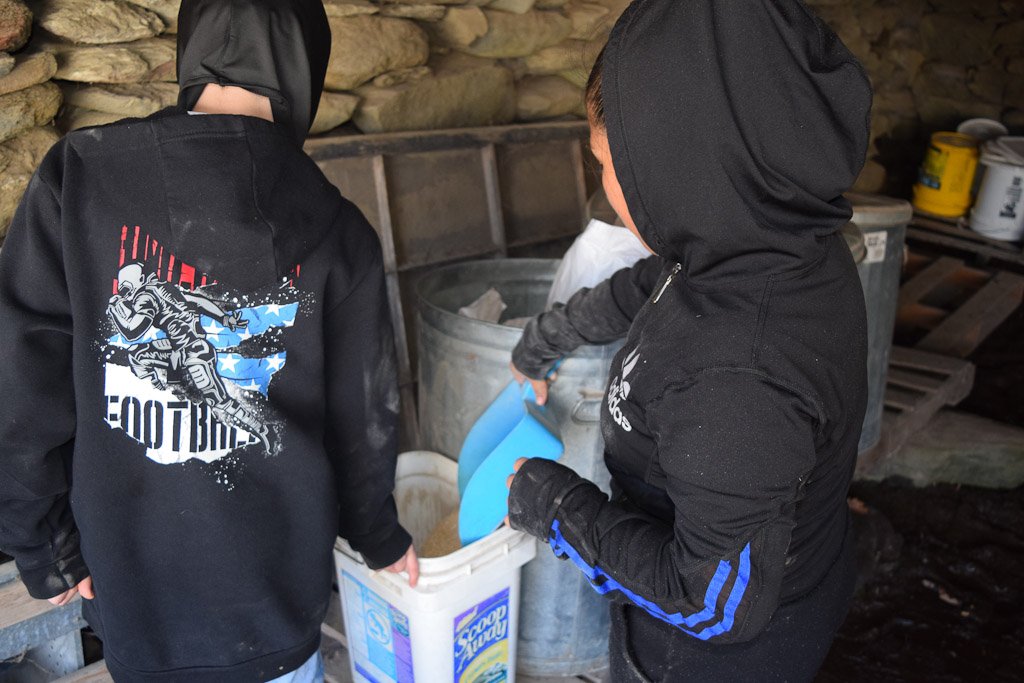

To start off, I have to figure out how much of each component went into one batch of grain. When mixing, we have buckets marked with lines to fill up to. In order to convert these lines into volume, I used a known measurement of water and kept adding until the line was reached. After having the volume in cups, I converted these quantities to gallons.

Since the goal is to figure out cost, and we purchase the components by weight, I have to convert volume to weight. I did this by weighing out a known volume of each component and calculating the density. By multiplying the volume per batch by the density, I got a list with the weight of each component in one batch of grain.

Then, I found the price of each component, and what quantity (in pounds) we buy them in. This allows me to calculate the price per pound. And with price per pound and pounds per batch, I can multiply to find the cost per batch by components.

The total cost for one batch of mixed grain is $23.22 and the total weight of one batch is 67.3 pounds. I can use proportions to find the cost per 50 pounds of mixed grain.

Without further ado, here are the results!

50 pounds of our mixed grain costs $17.25. One 50lb bag of layer pellets costs $16.59 so there is a price difference of only $0.66 per 50 pounds!